Rebar Solutions

REBAR SOLUTIONS AT AXISCORE

High-Strength Rebar Systems – Engineered for Structural Excellence

Axiscore Solutions Pvt Ltd provides complete mechanical splicing solutions for the construction industry. As a trusted manufacturer, supplier, and exporter of high-quality Rebar Couplers, we deliver reliable products backed by extensive expertise and industry experience.

Our progress is driven by a team of expert professionals whose commitment, integrity, and technical skill form the foundation of our high-performance culture.

For over a decade, our professionals have been trusted partners to some of the region’s most forward-thinking construction companies, offering dependable solutions rooted in our strong core values.

Our Couplers

COUPLER MATERIAL

Built Strong with Premium Steel Grades

All materials are tested and certified, meeting IS, BS, and ASTM standards.

At Axiscore Solutions Pvt Ltd, we use only high-grade materials for our rebar couplers to ensure unmatched strength, durability, and safety.

C45 Steel:

- A medium carbon steel known for high tensile strength and excellent machinability.

EN8 Steel:

- Offers superior strength and fatigue resistance. Perfect for load-bearing and critical construction applications.

EN8D Steel:

- Our enhanced EN8 variant, engineered for better corrosion resistance and performance under dynamic loads.

Why Choose Axiscore Couplers?

Our rebar couplers are manufactured to meet the stringent requirements of internationally recognized standards.

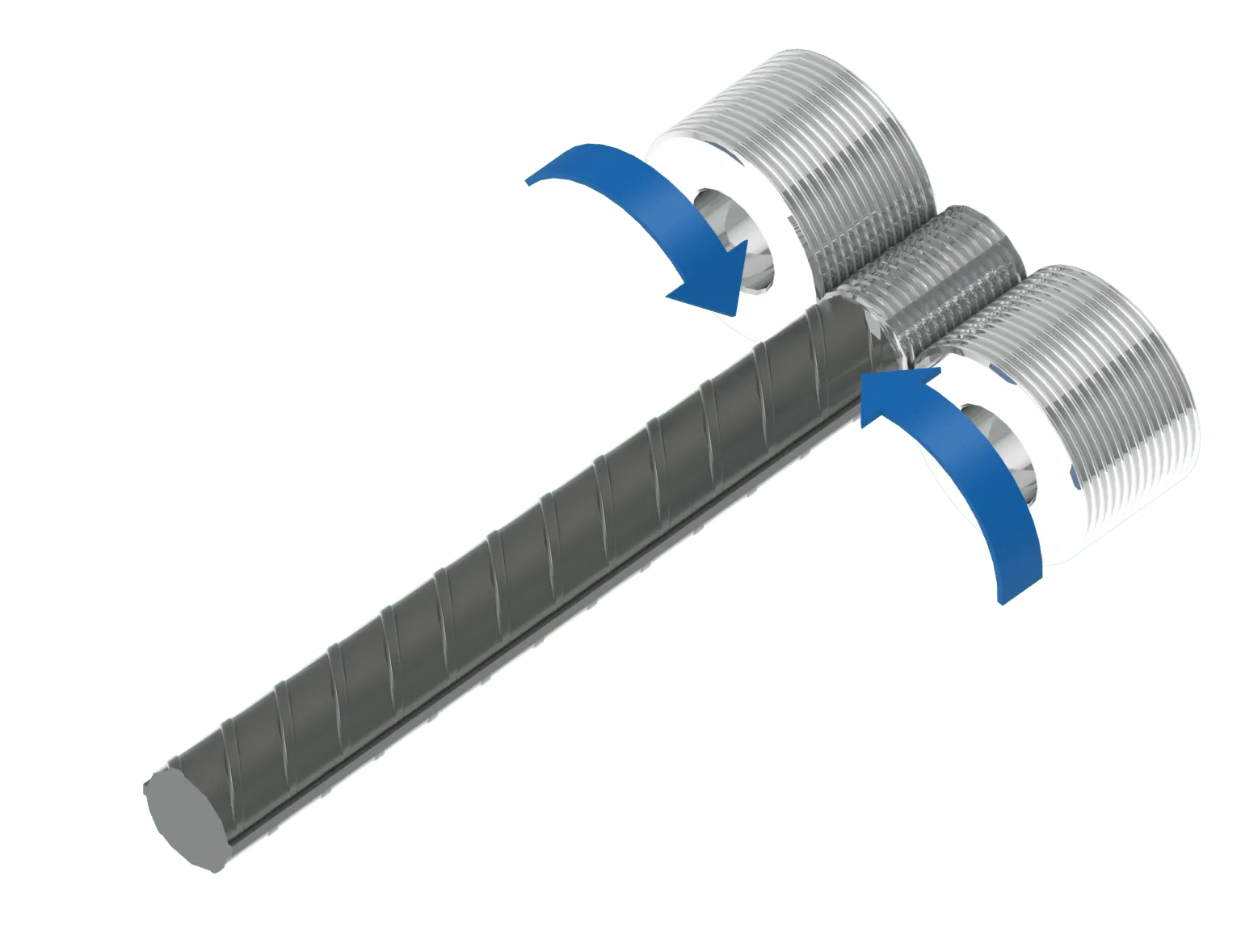

In reinforced concrete structures, mechanical rebar couplers and threading systems replace conventional lap splicing, ensuring stronger, more efficient connections. Designed with a high-performance parallel thread system, our couplers are engineered and produced to the highest quality specifications.

We offer a versatile range of rebar couplers suitable for most reinforcement connection applications. Available in sizes from 16 mm to 40 mm, they are designed for quick and straightforward on-site installation.

Threading Options for Every Project Need

At Axiscore Solutions Pvt Ltd, we understand that every project has unique technical requirements. That’s why our coupler solutions include both Rolltec Threading and Cold Forge Threading options

ROLLTEC

STEP 1: Peeling

STEP 2: Thread Rolling

Ideal for high-precision, consistent threads, Rolltec ensures optimal performance and durability under demanding site conditions.

FORTEC

STEP 1: Cutting

STEP 2: Cold Forging

STEP 3: Threading

This method enhances the core strength of the bar ends, delivering superior thread quality and excellent fatigue resistance.

What advantages does it bring to your project?

Cost-Efficient Construction

Reduces the amount of reinforcement required, achieving cost savings difficult to match with other components.

Faster Installations

Enables quicker assembly with less material handling, ensuring faster on-site installation.

Maximized Ductility

Facilitates full ductile elongation of reinforcing bars.

Reduced Steel Waste

Significantly cuts down on steel scrap and wastage.

Improved Structural Stability

Lower reinforcement density contributes to better structural performance.

Ready for Future Expansion

Couplers can be installed in advance for planned extensions, eliminating the need for protruding rebars and extensive concrete demolition.

Continuous Strength

Offers uninterrupted structural continuity with strength exceeding that of the rebar itself — a major advantage for multi-story structures.

Superior Load Transfer

Delivers exceptional structural integrity by ensuring mechanical joints rely less on concrete for load transfer.

Where Are Axiscore Mechanical Couplers Used?

High-rise buildings & towers

Bridges & flyovers

Tunnels & metro projects

Industrial & commercial structures

Retrofitting & extensions

Axiscore Couplers are now widely recommended in structural codes for critical projects due to their superior strength and reliability.

CONTACT US

Have questions?

Get in touch!

Get in touch with us today and discover how Axiscore Solutions Pvt Ltd can elevate the efficiency of your construction projects